What are the product standards for neutral point resistors?

What are the Product Standards for Neutral Point Resistors?

I. Introduction

Neutral Point Resistors (NPRs) play a crucial role in electrical systems, particularly in grounding applications. These components are essential for ensuring the safety and reliability of power generation and distribution systems. This blog post aims to explore the product standards for NPRs, highlighting their importance, regulatory frameworks, and best practices in the industry.

II. Overview of Neutral Point Resistors

A. Function and Application of NPRs

NPRs are used primarily in grounding systems to limit fault currents and stabilize the neutral point of transformers and generators. By providing a controlled path for fault currents, they help protect equipment and maintain system stability. In power generation and distribution, NPRs are vital for ensuring that electrical systems operate safely and efficiently.

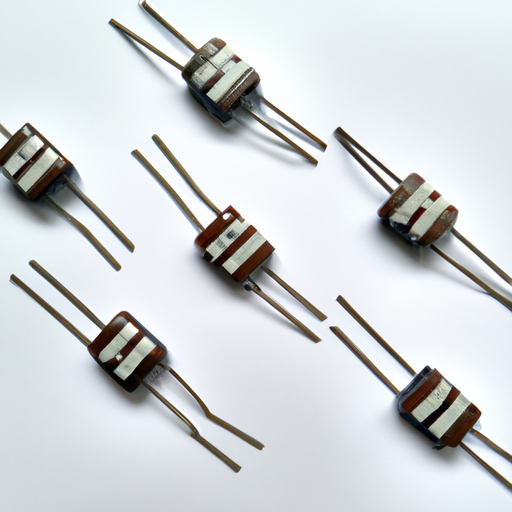

B. Types of Neutral Point Resistors

NPRs can be categorized into two main types: fixed resistors and variable resistors. Fixed resistors have a predetermined resistance value, while variable resistors allow for adjustments based on system requirements. This flexibility is particularly useful in applications where load conditions may change.

C. Key Characteristics of NPRs

The performance of NPRs is defined by several key characteristics:

1. **Resistance Value**: This is the nominal resistance of the NPR, which determines how much current can flow through it during a fault condition.

2. **Power Rating**: The power rating indicates the maximum amount of power the resistor can dissipate without overheating.

3. **Temperature Coefficient**: This characteristic describes how the resistance value changes with temperature, which is critical for maintaining performance under varying environmental conditions.

III. Regulatory Bodies and Standards

A. Overview of Relevant Regulatory Bodies

Several organizations establish standards for electrical components, including NPRs. Key regulatory bodies include:

1. **International Electrotechnical Commission (IEC)**: This organization develops international standards for electrical and electronic technologies.

2. **Institute of Electrical and Electronics Engineers (IEEE)**: IEEE standards are widely recognized in the electrical engineering community and cover various aspects of electrical systems.

3. **American National Standards Institute (ANSI)**: ANSI oversees the development of voluntary consensus standards for products, services, processes, and systems in the United States.

B. Key Standards Applicable to NPRs

Several standards are particularly relevant to NPRs:

1. **IEC 60076-6**: This standard pertains to power transformers and includes guidelines for the design and testing of NPRs used in transformer applications.

2. **IEEE C57.12.00**: This standard outlines general requirements for transformers, including performance criteria that NPRs must meet.

3. **ANSI C37.90**: This standard addresses relays and relay systems, which often incorporate NPRs for fault protection.

IV. Product Standards for Neutral Point Resistors

A. Electrical Performance Standards

1. **Resistance Tolerance**: NPRs must adhere to specified resistance tolerances to ensure they perform as expected under fault conditions.

2. **Power Dissipation Capabilities**: The ability to dissipate power without overheating is critical. Standards dictate the maximum power levels that NPRs can handle safely.

3. **Insulation Resistance**: High insulation resistance is essential to prevent electrical leakage and ensure safety in operation.

B. Mechanical Standards

1. **Construction Materials**: The materials used in NPRs must withstand environmental stresses, including temperature fluctuations and humidity.

2. **Environmental Resistance**: NPRs should be designed to operate effectively in various environmental conditions, including extreme temperatures and humidity levels.

3. **Vibration and Shock Resistance**: Mechanical robustness is vital, especially in applications where NPRs may be subjected to vibrations or shocks.

C. Safety Standards

1. **Overcurrent Protection**: NPRs must include features that protect against overcurrent conditions, which can lead to equipment damage or failure.

2. **Thermal Management**: Effective thermal management strategies are necessary to prevent overheating during operation.

3. **Compliance with Electrical Safety Regulations**: Adhering to safety regulations ensures that NPRs are safe for use in electrical systems.

V. Testing and Certification

A. Importance of Testing NPRs

Testing is crucial to ensure that NPRs meet the required performance and safety standards. Rigorous testing helps identify potential issues before the components are deployed in the field.

B. Common Testing Methods

1. **Electrical Testing**: This includes measuring resistance, power dissipation, and insulation resistance to verify electrical performance.

2. **Mechanical Testing**: Mechanical tests assess the durability and robustness of NPRs under various conditions.

3. **Environmental Testing**: Environmental tests evaluate how NPRs perform under extreme conditions, such as high temperatures or humidity.

C. Certification Processes

1. **Role of Third-Party Testing Organizations**: Independent testing organizations play a vital role in certifying that NPRs meet industry standards.

2. **Importance of Compliance with Standards**: Compliance with established standards is essential for ensuring the reliability and safety of NPRs in electrical systems.

VI. Industry Best Practices

A. Design Considerations for NPRs

1. **Selection of Materials**: Choosing the right materials is critical for ensuring the longevity and performance of NPRs.

2. **Design for Manufacturability**: NPR designs should consider ease of manufacturing to reduce costs and improve production efficiency.

B. Quality Assurance Processes

1. **In-Process Inspections**: Regular inspections during the manufacturing process help identify defects early.

2. **Final Product Testing**: Comprehensive testing of the final product ensures that it meets all performance and safety standards.

C. Documentation and Traceability

1. **Importance of Maintaining Records**: Keeping detailed records of testing and manufacturing processes is essential for quality assurance and compliance.

2. **Role of Documentation in Compliance**: Proper documentation supports compliance with industry standards and facilitates audits.

VII. Challenges and Future Trends

A. Challenges in Meeting Product Standards

1. **Evolving Technology**: As technology advances, NPRs must adapt to new requirements and standards.

2. **Increasing Demand for Reliability**: The growing need for reliable electrical systems places pressure on manufacturers to produce high-quality NPRs.

B. Future Trends in NPR Technology

1. **Advances in Materials Science**: New materials may enhance the performance and durability of NPRs.

2. **Integration with Smart Grid Technologies**: As smart grid technologies evolve, NPRs will need to integrate seamlessly with these systems to ensure optimal performance.

VIII. Conclusion

In summary, adhering to product standards for Neutral Point Resistors is essential for ensuring the safety, reliability, and efficiency of electrical systems. Manufacturers and users must prioritize compliance with established standards to mitigate risks and enhance performance. By understanding the importance of NPRs and the standards that govern them, stakeholders can contribute to the development of safer and more reliable electrical systems.

IX. References

1. IEC 60076-6: Power transformers.

2. IEEE C57.12.00: Standard for transformers.

3. ANSI C37.90: Relays and relay systems.

4. Additional resources for further reading on NPRs and electrical standards.

---

This blog post provides a comprehensive overview of product standards for Neutral Point Resistors, emphasizing their importance in electrical systems and the need for compliance with established standards. By following best practices and staying informed about industry trends, manufacturers and users can ensure the reliability and safety of their electrical systems.