What is a product of automotive resistors?

What is a Product of Automotive Resistors?

I. Introduction

In the intricate world of automotive engineering, every component plays a crucial role in ensuring the vehicle operates efficiently and safely. Among these components, automotive resistors are essential elements that help regulate electrical currents and maintain the functionality of various systems. This blog post will delve into the definition of automotive resistors, their importance in automotive applications, and the various types and characteristics that make them indispensable in modern vehicles.

II. Understanding Resistors

A. Basic Principles of Resistors

At its core, a resistor is an electrical component that limits or regulates the flow of electric current in a circuit. The fundamental principle governing resistors is Ohm's Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R) of the conductor. This relationship is expressed mathematically as:

\[ V = I \times R \]

Understanding this principle is crucial for grasping how resistors function within automotive systems.

B. Types of Resistors

Resistors come in various forms, each serving specific purposes:

1. **Fixed Resistors**: These resistors have a constant resistance value and are commonly used in circuits where a specific resistance is required.

2. **Variable Resistors (Potentiometers)**: These allow for adjustable resistance, making them ideal for applications like volume controls in audio systems.

3. **Specialty Resistors**: This category includes thermistors, which change resistance with temperature, and photoresistors, which vary resistance based on light exposure. These are particularly useful in automotive sensors.

III. Role of Resistors in Automotive Systems

A. Electrical Systems in Vehicles

Modern vehicles are equipped with complex electrical systems that control everything from engine performance to entertainment features. Resistors play a vital role in these systems by ensuring that electrical currents are appropriately managed, preventing damage to sensitive components.

B. Specific Applications of Automotive Resistors

1. **Engine Control Units (ECUs)**: Resistors are integral to ECUs, which manage engine functions. They help regulate signals from various sensors, ensuring optimal engine performance.

2. **Sensors and Actuators**: Resistors are used in various sensors, such as temperature and pressure sensors, to provide accurate readings. They also play a role in actuators, which convert electrical signals into mechanical movement.

3. **Lighting Systems**: In automotive lighting, resistors help control the brightness of lights and prevent overcurrent situations that could lead to bulb failure.

4. **Infotainment Systems**: Resistors are used in audio systems to manage sound levels and in navigation systems to ensure accurate data processing.

IV. Types of Automotive Resistors

Automotive resistors come in several types, each with unique properties suited for specific applications:

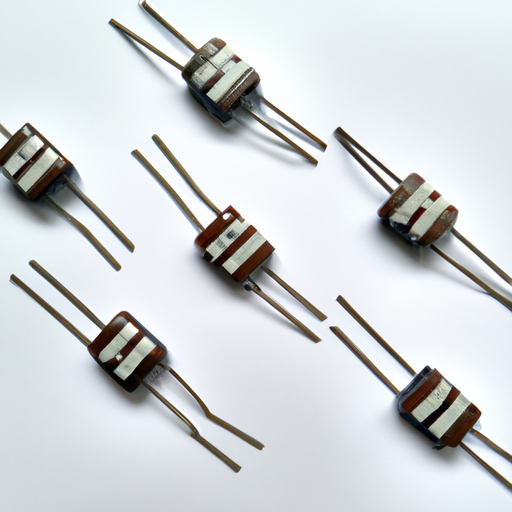

A. Carbon Composition Resistors

These resistors are made from a mixture of carbon and a binding material. They are known for their high energy absorption and are often used in applications where high pulse loads are expected.

B. Metal Film Resistors

Metal film resistors offer better stability and accuracy than carbon composition resistors. They are commonly used in precision applications, such as in ECUs and sensors.

C. Wirewound Resistors

These resistors are constructed by winding a metal wire around a ceramic or plastic core. They can handle high power loads and are often used in applications requiring high precision and reliability.

D. Thick and Thin Film Resistors

Thick film resistors are made by printing a resistive material onto a substrate, while thin film resistors are created using a similar process but with a thinner layer. Both types are used in various automotive applications due to their compact size and reliability.

E. Surface Mount Resistors

These resistors are designed for surface mounting on circuit boards, making them ideal for modern automotive electronics where space is at a premium.

V. Key Characteristics of Automotive Resistors

When selecting automotive resistors, several key characteristics must be considered:

A. Resistance Value and Tolerance

The resistance value determines how much current will flow through the resistor, while tolerance indicates how much the actual resistance can vary from the specified value. Both factors are critical for ensuring the proper functioning of automotive systems.

B. Power Rating

The power rating indicates the maximum amount of power a resistor can dissipate without failing. In automotive applications, resistors must be able to handle varying power loads, especially in high-performance vehicles.

C. Temperature Coefficient

This characteristic measures how much a resistor's resistance changes with temperature. Automotive resistors must maintain stable performance across a wide temperature range, as vehicles operate in diverse environmental conditions.

D. Reliability and Durability

Given the harsh conditions in which vehicles operate, automotive resistors must be highly reliable and durable. They should withstand vibrations, moisture, and temperature fluctuations without degrading in performance.

E. Environmental Considerations

Automotive resistors must be designed to resist environmental factors such as moisture and vibration, which can affect their performance and longevity.

VI. Manufacturing Process of Automotive Resistors

A. Materials Used in Resistor Production

The materials used in manufacturing automotive resistors vary based on the type of resistor being produced. Common materials include carbon, metal films, and ceramic substrates.

B. Steps in the Manufacturing Process

1. **Material Preparation**: Raw materials are prepared and processed to create the resistive element.

2. **Resistor Fabrication**: The resistive material is shaped and assembled into the desired form, whether it be a wirewound, film, or surface mount resistor.

3. **Testing and Quality Control**: Each resistor undergoes rigorous testing to ensure it meets specified resistance values, power ratings, and durability standards.

C. Innovations in Resistor Manufacturing

Advancements in technology have led to innovations in resistor manufacturing, including the development of more compact designs and materials that enhance performance and reliability.

VII. Challenges and Considerations

A. Heat Management in Automotive Applications

As vehicles become more advanced, managing heat generated by electrical components, including resistors, becomes increasingly important. Effective heat dissipation strategies are essential to prevent component failure.

B. Impact of Automotive Trends

The rise of electric vehicles (EVs) presents new challenges and opportunities for automotive resistors. As EVs rely heavily on electronic systems, the demand for high-performance resistors is expected to grow.

C. Regulatory Standards and Compliance

Automotive resistors must comply with various regulatory standards to ensure safety and performance. Manufacturers must stay updated on these regulations to maintain compliance.

D. Future Trends in Automotive Resistor Technology

The future of automotive resistors is likely to be shaped by advancements in materials science and manufacturing techniques, leading to more efficient and reliable components.

VIII. Conclusion

In conclusion, automotive resistors are vital components that play a significant role in the performance and safety of modern vehicles. Their ability to regulate electrical currents and support various systems makes them indispensable in automotive engineering. As the industry continues to evolve, the importance of high-quality automotive resistors will only increase, paving the way for innovations that enhance vehicle performance and safety.

IX. References

1. "Automotive Electronics: Principles, Technologies, and Applications" - Academic Journal

2. "Resistor Technology in Automotive Applications" - Industry Report

3. "The Future of Electric Vehicles and Their Components" - Research Paper

This blog post provides a comprehensive overview of automotive resistors, highlighting their significance, types, characteristics, and the challenges faced in the industry. Understanding these components is essential for anyone interested in automotive technology and engineering.