What is the mainstream capacitor computing production process?

What is the Mainstream Capacitor Computing Production Process?

I. Introduction

In the rapidly evolving landscape of technology, capacitor computing has emerged as a pivotal innovation, reshaping how we approach data processing and energy management. Capacitor computing leverages the unique properties of capacitors to perform computations, offering advantages in speed, efficiency, and energy consumption. This blog post will delve into the mainstream production process of capacitor computing, exploring its principles, applications, and the intricate steps involved in bringing this technology to life.

II. Understanding Capacitor Computing

A. Explanation of Capacitor Computing Principles

At its core, capacitor computing utilizes the fundamental properties of capacitors—devices that store electrical energy in an electric field. Capacitors can charge and discharge rapidly, making them ideal for high-speed computations. Unlike traditional computing methods that rely heavily on transistors, capacitor computing harnesses the ability of capacitors to represent and manipulate data through voltage levels.

1. Basic Concepts of Capacitors

Capacitors consist of two conductive plates separated by an insulating material, known as a dielectric. When voltage is applied, an electric field forms between the plates, allowing the capacitor to store energy. The amount of energy stored is proportional to the voltage and the capacitance value, which is determined by the surface area of the plates and the properties of the dielectric material.

2. Role of Capacitors in Computing

In computing, capacitors can be used to represent binary data (0s and 1s) based on their charge state. By manipulating these charge states, capacitors can perform arithmetic operations, memory storage, and signal processing. This approach offers a more energy-efficient alternative to traditional silicon-based computing, particularly in applications requiring rapid data processing.

B. Applications of Capacitor Computing

Capacitor computing finds applications across various domains, including:

1. Energy Storage

Capacitors are widely used in energy storage systems, providing quick bursts of energy for applications such as electric vehicles and renewable energy systems. Their ability to charge and discharge rapidly makes them ideal for stabilizing power supplies and enhancing energy efficiency.

2. Signal Processing

In signal processing, capacitors play a crucial role in filtering and amplifying signals. Capacitor computing can enhance the performance of audio and video processing systems, enabling clearer and more accurate signal transmission.

3. Data Processing

Capacitor computing is increasingly being explored for data processing tasks, particularly in high-performance computing environments. Its potential for parallel processing and low power consumption makes it an attractive option for future computing architectures.

III. The Production Process of Capacitor Computing

The production of capacitor computing involves several critical steps, each contributing to the final product's performance and reliability.

A. Raw Material Selection

1. Types of Materials Used

The choice of materials is fundamental in capacitor computing. Common materials include various metals for conductive plates, such as aluminum and tantalum, and a range of dielectrics, including ceramics and organic compounds. The selection of these materials directly impacts the capacitor's performance characteristics, such as capacitance, voltage rating, and temperature stability.

2. Importance of Material Quality

High-quality materials are essential for ensuring the reliability and longevity of capacitors. Impurities or defects in the materials can lead to failures, affecting the overall performance of the computing system. Manufacturers often conduct rigorous testing and sourcing to ensure that only the best materials are used in production.

B. Design and Prototyping

1. Circuit Design Considerations

The design phase involves creating circuit layouts that optimize the use of capacitors for computing tasks. Engineers must consider factors such as capacitance values, voltage levels, and the arrangement of capacitors within the circuit to achieve the desired performance.

2. Simulation and Testing of Prototypes

Before moving to full-scale production, prototypes are developed and tested. Simulation software allows engineers to model the circuit's behavior under various conditions, identifying potential issues and optimizing performance. Physical prototypes are then built for real-world testing, ensuring that the design meets the required specifications.

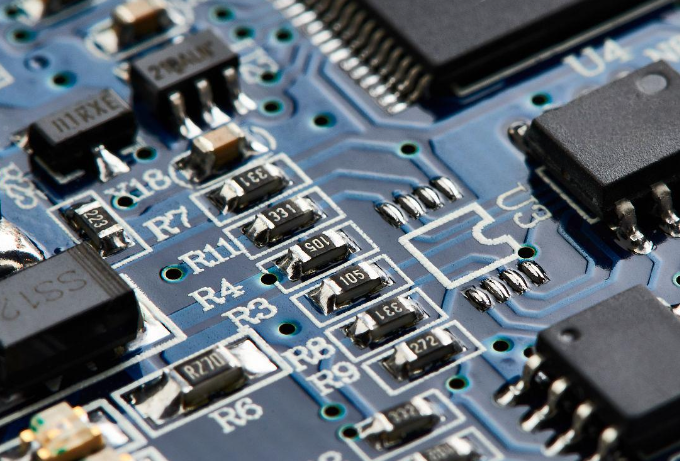

C. Fabrication Techniques

The fabrication of capacitor computing components involves several advanced techniques:

1. Thin-Film Deposition

Thin-film deposition is a critical process in creating the layers of capacitors. Techniques such as chemical vapor deposition (CVD) and physical vapor deposition (PVD) are used to apply thin layers of materials with precise control over thickness and composition.

2. Etching Processes

Etching is employed to define the patterns of the capacitor components on the substrate. This process can be done using wet or dry etching techniques, allowing for the precise removal of material to create the desired shapes and structures.

3. Layering and Assembly

Once the individual layers are created, they are assembled into a complete capacitor unit. This may involve stacking multiple layers of dielectric and conductive materials, followed by encapsulation to protect the components from environmental factors.

D. Quality Control Measures

Quality control is paramount in the production of capacitor computing components. Manufacturers implement several measures to ensure that each product meets industry standards.

1. Testing for Electrical Performance

Electrical performance testing is conducted to verify that the capacitors function as intended. This includes measuring capacitance, voltage ratings, and leakage currents to ensure compliance with specifications.

2. Reliability Testing

Reliability testing assesses how well the capacitors will perform over time under various conditions. This may involve accelerated aging tests, thermal cycling, and humidity exposure to simulate real-world usage.

3. Compliance with Industry Standards

Manufacturers must adhere to industry standards and regulations, such as those set by the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE). Compliance ensures that the products are safe, reliable, and suitable for use in various applications.

IV. Integration into Computing Systems

A. Incorporating Capacitor Computing into Existing Architectures

Integrating capacitor computing into existing computing architectures presents both opportunities and challenges. Capacitor-based systems can enhance performance in specific applications, but they must be compatible with traditional components to ensure seamless operation.

B. Challenges in Integration

1. Compatibility with Traditional Components

One of the primary challenges is ensuring that capacitor computing components can work alongside conventional silicon-based systems. This may require the development of hybrid architectures that can leverage the strengths of both technologies.

2. Performance Optimization

Optimizing performance is crucial for successful integration. Engineers must fine-tune the interactions between capacitor computing components and traditional processors to achieve the desired speed and efficiency.

C. Future Trends in Capacitor Computing Integration

As capacitor computing technology matures, we can expect to see increased integration into mainstream computing systems. Advances in materials science and fabrication techniques will likely lead to more efficient and powerful capacitor-based computing solutions, paving the way for new applications in artificial intelligence, machine learning, and beyond.

V. Case Studies and Real-World Applications

A. Examples of Capacitor Computing in Use

Capacitor computing is already making waves in various sectors:

1. Consumer Electronics

In consumer electronics, capacitor computing is used in devices such as smartphones and tablets, where energy efficiency and processing speed are critical. Capacitors help manage power consumption, extending battery life while maintaining high performance.

2. Industrial Applications

In industrial settings, capacitor computing is employed in automation systems and robotics, where rapid data processing and energy management are essential for efficiency and productivity.

3. Research and Development

Research institutions are exploring capacitor computing for advanced computing applications, including quantum computing and neuromorphic computing, where traditional methods may fall short.

B. Impact on Performance and Efficiency

The integration of capacitor computing has demonstrated significant improvements in performance and efficiency across various applications. By reducing energy consumption and enhancing processing speeds, capacitor computing is poised to play a crucial role in the future of technology.

VI. Conclusion

In summary, the production process of capacitor computing is a complex and multifaceted endeavor that involves careful material selection, innovative design, advanced fabrication techniques, and rigorous quality control. As this technology continues to evolve, its applications will expand, offering new possibilities for energy-efficient computing solutions. The future of capacitor computing holds great promise, and continued innovation in this field will be essential for meeting the demands of an increasingly digital world.

VII. References

- Academic Journals

- Industry Reports

- Relevant Books and Articles

This blog post provides a comprehensive overview of the mainstream capacitor computing production process, highlighting its principles, applications, and the intricate steps involved in its production. As technology advances, capacitor computing will undoubtedly play a significant role in shaping the future of computing.